June 1, 2019 | 8:00 AM CDT

High velocity natural gas pipelines pose a unique challenge in terms of effective cleaning for corrosion mitigation purposes or pre ILI runs. Studies show that the best cleaning occurs when the tool runs at approximately 8 mph allowing brushes and discs to do their job, where at speeds over 10mph they can bypass the debris and liquids, proving ineffective.

To meet this challenge, Inline Services has designed and manufactured a new series of Speed Control Cleaning Pig (SCP) Tools ranging from 30” to 48”. The SCPs onboard technology maintains optimal cleaning speeds of 6 to 10 mph within a gas flow velocity of up to 33mph. In addition, the SCPs IMU collects performance data that can be exported onsite.

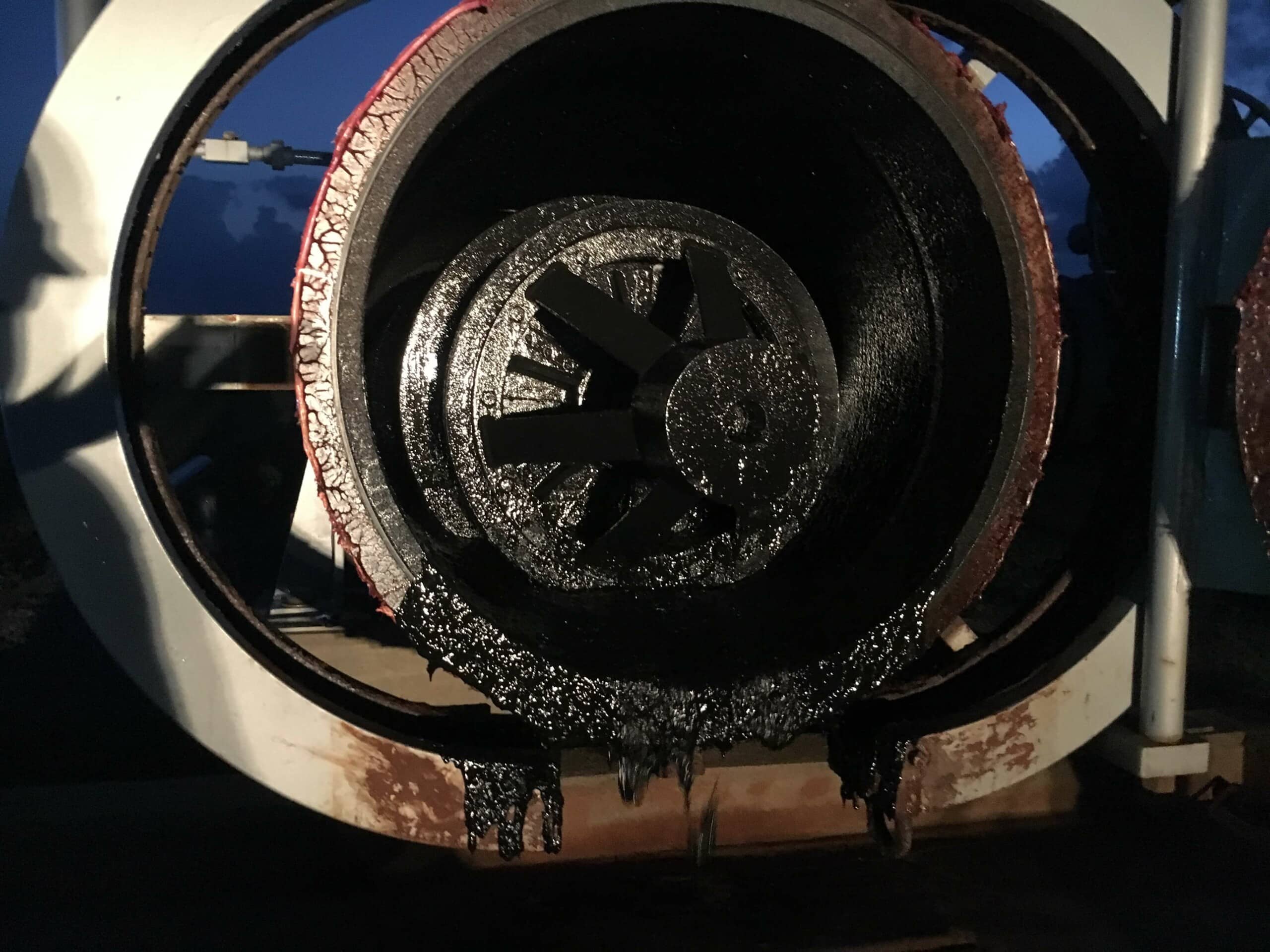

Inline’s new SCP recently exceeded expectations during a run in 30” and 36” pipelines containing numerous 1.5D short radius bends. While the normal gas flow velocity was maintained, the tool averaged an ideal control speed of 7mph, allowing for both efficient cleaning and no interruption of gas delivery. In addition, the pig played an integral part in the effective use of chemicals and inhibitors, determining quantities spread, recovery and liquids balance within the pipeline.

Following each run, the IMU data was downloaded and analyzed onsite. In addition, the pigs were reconfigured on location with cups, discs, brushes, magnets and tracking transmitters to prepare for the next run.

For more information about this project, or to discuss how Inline Services can improve your Natural Gas Pipeline Integrity Program through dependable Speed Controlled Cleaning Pig (SCP) Tools and other pigging solutions contact one of our Pigging Experts at 888.973.0079, or use the “Ask An Expert!” form on this page to contact us via email.